News

Pulsating vacuum high-pressure double-door steam sterilizer

1. Pulsating vacuum high-pressure steam sterilizer should be selected for the mushroom bag center

The cultivation of edible fungi uses agricultural and sideline product pellets. The microorganisms the surface

are dormant in a dry state. When water is added and stirred, the microorganisms are revi

and the rich nutrients in the culture medium accelerate the reproduction of microorganisms. Use high temperature,

normal pressure or high pressure to kill microorganisms to ensure pure culture of edible fungi strain

The mushroom bag center needs to produce continuously and no mistakes are allowed. In the past, the

single-door sterilizer was directly placed in the dust cultivation bag packaging workshop after sterilization,

increasing the risk of contamination. Although disinfection is performed before inoculation, it is not absolute.

Therefore, a double-door sterilizer is designed, and the front and back sections are separated by a wall.

The front end is a mixing and packaging workshop, the environment is relatively dirty, and sterilization

2. Sterilization principle of vacuum sterilizer

The vacuum high-pressure steam sterilizer exhausts the air in the pot by vacuuming. When the vacuum degree

reaches -15 kPa, the remaining cold air has no effect on the sterilization effect. The pulsating vacuum exhaust

method is used to vacuum and pass steam multiple times to exhaust the air so that there are no cold spots in

the pot. When the cultivation bag is in a vacuum state, the sterilization steam quickly penetrates the sterilized

object to achieve thorough sterilization.

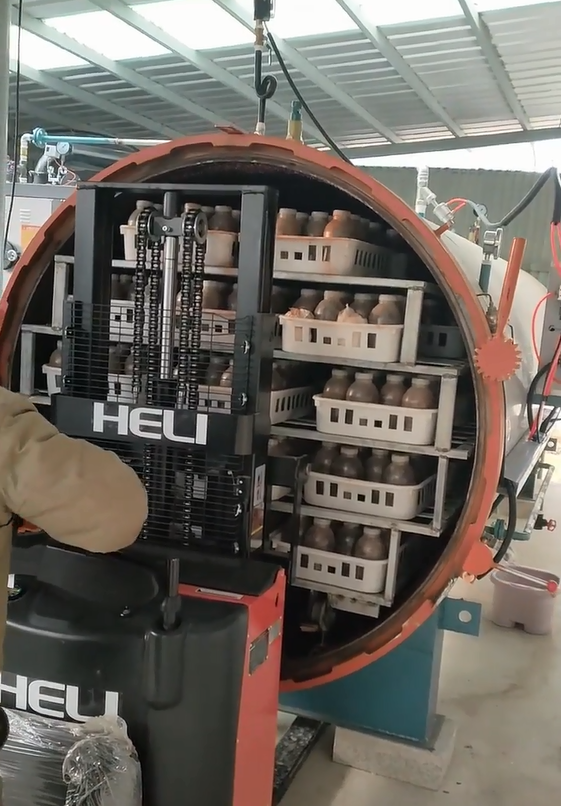

3. Mode of entering and exiting the sterilizer

Traditional trolley entry and exit mode: The traditional mode relies on manual placement of the cultivation bag

basket on the trolley and then pushes it into the sterilizer, which is inefficient; the pot is hot, the working

environmeis poor, and the personnel mobility is large; a special person is also required to repair the wheels of

the trolley (the wheels of the trolley are equipped with bearings and butter lubricant is added. Under high temperature and

high pressure, the butter is lost and cannot play a lubricating role). In the past, most of the sterilization trolleys were

welded by angle irons, and they were often corroded after a few years of use. Now hot-dip galvanized materials or

stainless steel are mostly used for sterilization racks, and forklifts are used to enter and exit the pot.

Forklift entry and exit sterilization pot mode: Domestic large enterprises often use forklifts to transport cultivation bag

baskets to the sterilizer. The cultivation bag basket is placed on the sterilization shelf through the upper basket machine,

and the forklift is sent into the sterilizer for sterilization. There is also a semi-automatic mode for in and out of the pot.

After sterilization, the electric car takes out the sterilization rack and places it in the cooling room, parallel to the direction

of the cold air for cooling.

Categories

Contact Us

- +86 15093267083

- +86 15093267083

- amy@zzbelead.com

- +8615093267083